Understanding the intrinsically flawed systemic functions of production in the fashion industry is crucial to changing our relationship to consumption. While sustainability has become somewhat chic to wax lyrical about, especially in the realm of marketing, I wanted to develop a deeper understanding of the necessity for implementing production strategies outside of the linear model currently in use; this is where the compelling concept (and actionable, at that) of circularity comes in; in which products are designed to be enhanced in function over a period of time, without the need to be discarded at the alarming rate currently exercised in our “throwaway” culture — en masse, and all the time. This deeply insightful conversation with Michelle Gabriel, Professor of Sustainable Fashion Strategy at Glasgow Caledonian New York College (GCNYC), enriched my perspective of the considerations for change in the industry, and the dire implications if we choose otherwise — reaffirming that while corporate institutions might lead to a jaded view on sustainability, there are truly spaces like GCNYC intent on forging inquiry into the possibilities ahead for ethical re-workings of the monolith that is “fashion”; and that all is not lost to the industrial progression of most societies — predicated foremost by western capitalist, neo-colonial domination of the planet. It is through this frank conversation, that I hope the appeal and viability of circularity is seeded in your relationship to sartorial consciousness.

What are the key differences between our current linear model of consumption, and establishing circularity in fashion?

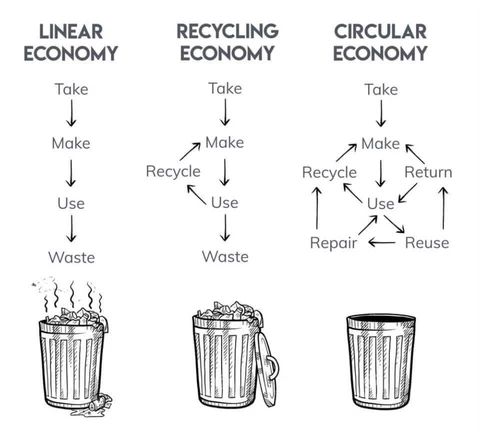

Michelle Gabriel: The basic difference between a linear model and a circular model of operation, is [that] a linear model extracts a raw material, utilises it in producing a good, and then that good is disposed of after use — while a circular model seeks to create an ecosystem where raw material inputs are never discarded and are instead utilised for reuse in other products at the end of use. In a linear model, value is extracted, reduced through use, and discarded when the value is felt to be close to nil. A circular model seeks to approach value differently by maintaining the value of that extracted raw material through appropriate product design, use phase considerations, and recapturing of the materials when the value of the product is diminishing so that they might be used as the raw material inputs at the start of a new cycle. One of the goals of a circular model is to reduce the need for virgin raw materials which are often extracted at a great cost to people, the planet and societies.

Circularity is a conversation in many industries but is very present in fashion. This is because of the industry’s highly dependent nature on virgin raw materials such as cotton, polyester and nylon, needed to produce goods and the very high production and consumption rate we have for fashion items such as clothing, shoes, handbags and accessories. Cotton — as an example — is a very water-intensive crop, and if not grown organically [it] often utilises many chemicals including fertilisers and pesticides to ensure high yields. Because of the high demand for cotton across the world, [it] is frequently grown in areas that can’t naturally support its needs thus diminishing natural water sources in service of irrigation, reducing the available drinking water in regions with pre-existing water scarcity issues. Most cotton grown today is not organic and utilises the chemicals mentioned earlier, causing community water sources near cotton fields to be polluted. I haven’t even mentioned the CO2 emissions included in these processes. I could go on regarding cotton, but this is all to say that circularity seeks to remedy the need to create and extract virgin cotton, thus reducing the scale of the effects mentioned. If we could keep a raw material viable through several cycles of use, through iterations of several new products across a given period of time, we might be able to reduce GHG emissions, be better stewards of water across the globe, and reduce water pollution.

There are a myriad challenges for fashion on its journey to be more circular. The industry creates uncountable new products a year, each with different components, which in turn have different needs in order to become part of a circular economy. That unique quality makes coming up with a universal, or at least a widely used, solution doubly challenging as a solution may only work for one raw material, across a product category which could have raw material components from hundreds of different sources across fabric, trims, and finishes. Infrastructure is necessary to drive the fashion industry towards greater circularity. What machinery or technology is needed to break down a garment into its separate component parts? How do you separate a polyester back neck label from a garment that is made from a fabric blend of cotton and spandex while removing the corozo nut buttons and the metal and nylon zipper? Don’t forget about that pesky polyester thread that the whole thing is sewn together with! Once you are able to separate these raw material components, how do you process them to ensure they are maintaining or growing in value and not degrading? How do you ensure performance, or look, or quality is viable from this processed material? How do you decide what new product to make from this revived material, all while ensuring you can recapture again to make something new and valuable at the end of this next use cycle? How do you sell the idea of this new material back to an industry which expects the look, style, and performance of the traditional virgin material? How do you get consumers to value this new material the same, or more as the thing they’re used to?

Investment in innovation is also a roadblock to [a] meaningful movement towards circularity for the fashion industry. How do we get all the above mentioned infrastructure? Industries with high levels of innovation have business models which apportion a significant amount of an organisation’s budget to innovation. They utilise that budget to come up with solutions that help to create new market opportunities for the organisation to compete within in the future. Those solutions also help manage risk, aid in organisational and industry differentiation and lead to valuable owned IP for companies. The fashion industry has an untenable business model. This is becoming a growing conversation — several sections of the 2021 BOF/McKinsey State of Fashion speaks to this argument — and explain the challenges in innovation across the industry. If you have a business model which, at best, every little thing goes exactly as planned, you are looking at a 10% profit margin [and] you do not have funds you can set aside for innovation. With that, you are also paying below living wages across your supply chain and paying poorly at [the] home office. This dynamic is possible because the fashion industry is a market of exceedingly low differentiation. Increasingly we are seeing [organisations] continue to eek by with even smaller margins, 2-5% and feeling they are surviving, which is [unbelievable]. This leads to a deep scarcity mindset across the industry which affects everything and a complete absence of innovation. As you can see, innovation and differentiation have a relationship that can either propel a business or industry upward into greater margins — or ensure a race to the bottom. Unfortunately, the fashion industry is currently in a race to the bottom.

The last fundamental challenge for the fashion industry in its journey towards circularity is scale. The enormous scale of the industry itself and the problems it finds itself facing are forcing people to look for enormous, silver bullet solutions. Circularity is an effort which requires many, many small consequential decisions made by many, many individual actors in concert. It is easiest to implement in a closed bubble where most of the inputs and processes can be well controlled. How does one implement circularity for a system that grows its cotton in India, spins its yarn in Taiwan, weaves its fabric in China, cuts its fabric in Brooklyn, sews its garments in Manhattan, and sells its final products internationally?

Should the system around production change due to consumer demand, or do companies have a responsibility to facilitate it nonetheless?

Michelle Gabriel: I do not believe the responsibility should be on the consumer for shifts in the industry. Right now, the fashion industry is nearly entirely self-regulated. The industry is putting a lot of effort into sustainability lip service through voluntary commitments, clever marketing endeavours, the seemingly millions of fashion sustainability conferences that now take place each year, and tackling sustainability, circularity, and positive impact initiatives in the shallowest ways possible for companies to get the credit but bear the least cost or pain from the efforts. These efforts give an illusion that there is momentum and action taking place that is leading to meaningful environmental and social change. But despite these (and other) efforts, almost nothing is being tangibly done to dynamically change the industry to increase its total viability, mitigate risks, reduce known negative impacts or even capture valid, usable data. Those with [the] power to affect change in the fashion industry, are only interested in sustainability as long as it doesn’t significantly disrupt current behaviours or operations. But sustainability, circularity and positive impact are intended to be revolutionary frameworks that cause the fashion industry to rethink the very core of its values, operations, and [the] way it does everything.

So, you have an industry with the power to change but not the will to do so, regulating itself, setting its own standards, and utilising voluntary commitments as the primary mechanism to police itself. Given that dynamic, how can you put industry change on consumers? Conversations around consumer responsibility for the supply chain and value chain challenges are intentional misdirection from an industry that really doesn’t want anyone looking too closely at the things it’s doing and not doing. Where consumers do bear a responsibility is in reevaluating their relationship to consumption. Overconsumption is the foundation on which the current fashion industry is built. That low differentiation I mentioned before, is a fundamental component in many of the industry’s challenges. Low differentiation creates an industry that can only achieve growth by forcing more goods on people, instead of by carving out more value per item (ie: more margin). This process of consuming more fashion — buying more, owning more, discarding more — has been supported through the advent of fast fashion in the early 2000s but is now normalised into the culture of the US and increasingly the world. Rethinking our participation in a consumption cycle which is extractive and results in many negative consequences is a revolutionary individual act which we can put on consumers.

How viable is circularity as a long-term, effective solution to production waste?

Michelle Gabriel: It is important to see circularity as a solution in a dynamic; where many solutions are necessary to tackle the litany of problems facing the fashion industry, including managing production waste. Circularity as a silver bullet is not viable, reasonable, nor a recipe for success. Circularity as part of a comprehensive tool-belt used across many value chain stakeholders is possible. To address production waste — and let’s say that includes industrial production waste and the waste of overproducing finished goods — you need to address all the areas I mentioned before. Every stage of production, every roadblock, every challenge. Some of those issues would be helped by circular practices, however, some might also be helped by reviewing the underlying structure of the fashion industry and fashion business. We have the challenges we do, as an industry, because our models and systems are massively inefficient and we don’t have a lot of innovation.

What are some other ways we can address our “throw-away” culture and obsession with novelty /fleeting trends?

Michelle Gabriel: There is likely some soul searching that each of us has to endeavour to think about what we have internalised that drives us to acquire so many things and thus need to discard so many things. Our level of consumption has affected the architecture we now build (a walk-in closet and a three-car garage isn’t a common feature in a pre-war home), the shows we watch (Hoarders, Tidying Up with Marie Kondo), and has created [entirely] new industries to help us manage or offload our things (self-storage facilities, personal organisers, eBay). Is that good or bad, and do we like how it makes us feel? Are we living in a society and a world that we like or might we change some of these issues if we could?

Aside from that fundamental step, there are several ways to make better choices. Purchase for longevity, shop second hand, buy from shops or companies local to your community, and stop before purchasing to ask yourself, “do I really need this?” The reality is small decisions matter, being conscientious matters, doing your part matters. We don’t get to big industry or societal change by someone snapping their fingers; we get there from billions of small movements which collectively amount to something new. We didn’t get to where we are quickly. We won’t get ourselves out of it quickly. If we know that it is going to take a lot of work, a lot of different solutions, and each of us doing what we can then there we go, there’s a plan. If we wait around for some quicker, more convenient solution we will be disappointed and in a place that is likely much scarier than we find ourselves today.